An air compressor is a device that converts power into potential energy stored in pressurized air. It is one of the most important pieces of equipment used in industrial and commercial applications, such as powering pneumatic tools, providing breathable air for workers in hazardous environments, and controlling process variables in manufacturing operations.

Scroll air compressors are a type of air compressor that use two interlocked spiral-shaped scrolls, or rotors, to pressurize and compress air. The scroll compressor is one of the most efficient and reliable types of air compressors on the market, and it is used in a wide range of industries and applications. In this article, we will explore what scroll air compressors are, how they work, and the different types of scroll air compressors available.

How Scroll Air Compressors Work

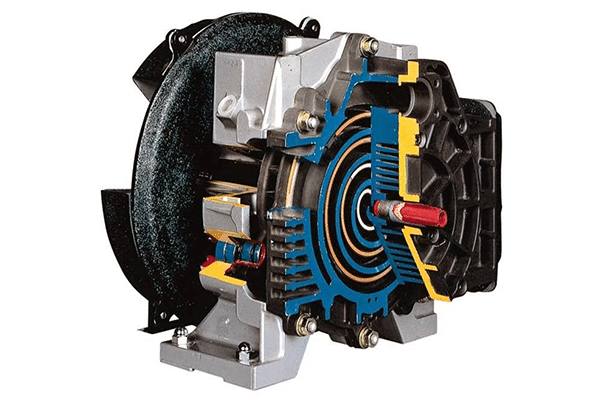

Scroll air compressors are powered by an electric motor and work by trapping air between two interlocked spiral-shaped rotors, or scrolls, that are mounted on the same shaft. As the rotors rotate, the air is drawn in from the intake port and trapped between the two scrolls. The two scrolls then rotate in opposite directions, trapping the air in the center of the scrolls and compressing it. When the air is compressed, it is pushed out through the discharge port and into the air tank or other device.

One of the key advantages of scroll air compressors is their high efficiency. By utilizing two rotors that move in opposite directions, they are able to pressurize and compress air more efficiently than other types of air compressors. Additionally, scroll air compressors are quieter and more reliable than other types of compressors, making them an ideal choice for applications where noise or reliability is a concern.

Types of Scroll Air Compressors

There are several different types of scroll air compressors available on the market, each designed for specific applications.

1. Single-Stage Scroll Compressors: These are the most common type of scroll air compressors, and they are ideal for applications that require low to moderate levels of pressure.

2. Two-Stage Scroll Compressors: This type of scroll compressor is designed for applications that require high levels of pressure, such as oil and gas production.

3. Variable-Speed Scroll Compressors: These compressors are designed to adjust their speed automatically in order to maintain the desired pressure. This type of scroll compressor is ideal for applications that require precise pressure levels.

Conclusion

Scroll air compressors are a type of air compressor that utilizes two interlocked spiral-shaped rotors to pressurize and compress air. They are highly efficient, reliable, and quiet, making them an ideal choice for a wide range of industrial and commercial applications. There are several different types of scroll air compressors available, each designed for specific applications.