Air compressors are powerful machines that are used to transform atmospheric air into pressurized air. This pressurized air is then used in a variety of applications, such as powering tools and machinery, and inflating tires and other inflatable items. An air compressor air delivery system is the mechanism by which pressurized air is delivered to the intended application. This article will provide an overview of the components of a typical air compressor air delivery system, and discuss how they work together to provide pressurized air.

1. Air Compressor

The main component of an air compressor air delivery system is the air compressor itself. Air compressors are powered by an electric motor or a gas engine, and use these to drive a set of crankshaft-connected pistons. These pistons draw air from the atmosphere and compress it into a small space, usually within the air compressor’s tank. The air compressor’s tank is designed to contain the compressed air at a pressure that is higher than atmospheric pressure.

2. In-Tank Check Valve

The in-tank check valve is a key component of an air compressor air delivery system. This valve is located between the compressor and the tank, and it is responsible for allowing compressed air to flow from the compressor into the tank and preventing air from flowing back into the compressor. Without this check valve, the compressor would be unable to produce air pressure.

3. Delivery Hose

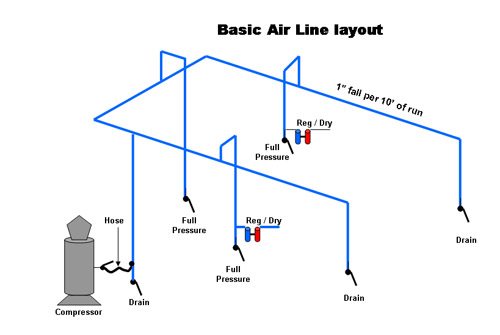

The delivery hose is responsible for transporting the pressurized air from the air compressor’s tank to the intended application. The delivery hose is typically made from a flexible material, such as rubber or plastic, and is connected to the tank via a fitting. The delivery hose is designed to be able to withstand the pressure of the compressed air, and is usually attached to a regulator that can be used to control the flow and pressure of the air.

4. Air Regulator

The air regulator is a key component of an air compressor air delivery system. This device is attached to the delivery hose, and it is responsible for controlling the flow and pressure of the compressed air. The air regulator can be adjusted to provide the desired pressure and flow rate for the intended application.

Conclusion

An air compressor air delivery system is responsible for delivering pressurized air to an intended application. This system consists of a compressor, an in-tank check valve, a delivery hose, and an air regulator. The compressor is responsible for compressing atmospheric air into a tank. The in-tank check valve prevents compressed air from flowing back into the compressor. The delivery hose transports the compressed air from the tank to the intended application, and the air regulator is used to control the pressure and flow rate of the air. Together, these components work to provide pressurized air for a variety of applications.