A duty cycle is a measure of the amount of time a particular device can be used before it needs to be turned off for a period of time in order to protect itself from overheating. This is especially important for air compressors, which can run for long periods of time and generate a lot of heat. In this article, we’ll explain what duty cycles are, how they work, and why they’re important for air compressors.

What is a Duty Cycle?

Contents

A duty cycle is a measure of the amount of time a particular device can be used before it needs to be turned off for a period of time in order to protect itself from overheating. This is especially important for air compressors, which can run for long periods of time and generate a lot of heat. Generally speaking, the longer a compressor runs, the more heat it will generate.

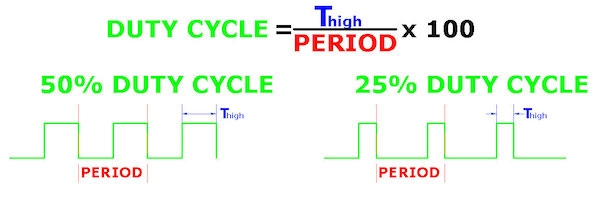

The duty cycle of an air compressor is determined by the manufacturer and is usually expressed as a percentage. A 100% duty cycle means that the compressor can run continuously without any breaks, while a 50% duty cycle means that the compressor can run for half the time and must be allowed to rest for the other half.

How Does a Duty Cycle Work?

A duty cycle works by controlling the amount of time that a compressor can be used before it needs to be turned off to cool down. This is especially important for air compressors, which can generate a lot of heat during operation and need to be allowed to cool down periodically to keep from overheating.

The duty cycle determines how often the compressor needs to be turned off and allowed to cool down. For example, a 100% duty cycle air compressor can run continuously without any breaks, while a 50% duty cycle compressor must be turned off and allowed to cool down for half of the time that it is used.

Why is a Duty Cycle Important for Air Compressors?

A duty cycle is important for air compressors because it helps protect the compressor from overheating. Air compressors generate a lot of heat during operation, and if they are not allowed to cool down periodically, they can become damaged or even destroyed.

The duty cycle of an air compressor is determined by the manufacturer, and it is important to follow the manufacturer’s instructions for how often the compressor needs to be turned off and allowed to cool down. For example, a 100% duty cycle air compressor can run continuously without breaks, while a 50% duty cycle compressor must be turned off and allowed to cool down for half of the time that it is used.

In addition, it is important to ensure that the air compressor is properly sized for the job that it is being used for. If an air compressor is too large for the job, it can generate more heat than it is capable of dissipating, leading to overheating and possible damage to the compressor.

Conclusion

Duty cycles are an important part of air compressor operation, as they help protect the compressor from overheating. By understanding what duty cycles are, how they work, and why they’re important for air compressors, you can ensure that your compressor is operating safely and efficiently. In particular, it is important to follow the manufacturer’s instructions for how often the compressor needs to be turned off and allowed to cool down, as well as to ensure that the compressor is properly sized for the job.