Compressed air systems are a staple of the modern industrial landscape, and their success is largely due to their ability to provide a reliable and cost-effective source of energy for a variety of processes. However, compressed air systems are also prone to a number of problems, most notably the presence of moisture in the air. This moisture can cause corrosion and other damage to the system, leading to costly repairs and downtime. To prevent this, membrane air dryers have become an essential component of any compressed air system.

What is a Membrane Air Dryer?

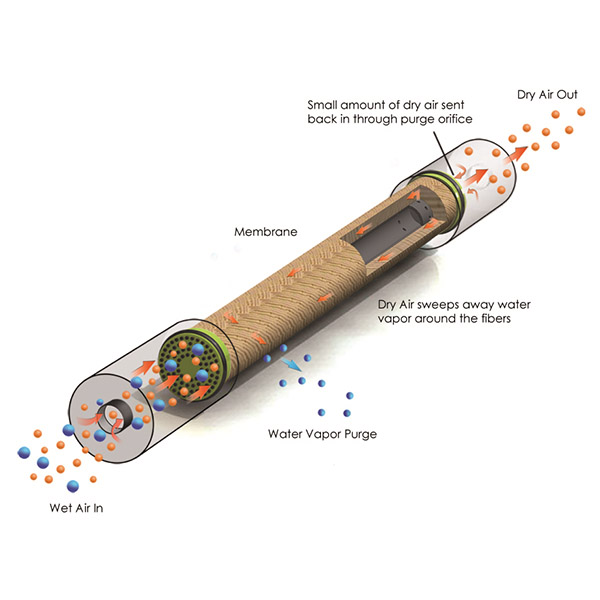

A membrane air dryer is an industrial device that is used to remove moisture from air before it enters a compressed air system. The dryer consists of a series of hollow fibers which are designed to absorb and remove moisture from the air. The fibers are made from a semi-permeable material, meaning that only water molecules can pass through the membrane, while air is blocked. As air passes through the dryer, the moisture is drawn out of the air, leaving it dry and free of moisture.

The Benefits of Using a Membrane Air Dryer

The use of a membrane air dryer in a compressed air system offers a number of benefits, including:

- Increased efficiency: By removing moisture from the air, the system is able to run more efficiently and with less strain on the components. This can result in significant cost savings over time.

- Improved performance: The absence of moisture in the air reduces the risk of corrosion and other damage to the system, leading to improved performance and longer equipment life.

- Reduced downtime: By preventing moisture from entering the system, the risk of downtime caused by damage to the system is reduced.

- Lower maintenance costs: As the system is less prone to damage due to moisture, the need for expensive maintenance or repairs is reduced.

Conclusion

Membrane air dryers are an essential component of any compressed air system. The use of a membrane air dryer can help to reduce moisture in the air, leading to improved performance, increased efficiency, reduced downtime, and lower maintenance costs. For these reasons, it is highly recommended that any compressed air system be equipped with a membrane air dryer.