Air compressors are essential tools used in many industrial and household settings to provide compressed air for a variety of purposes. To ensure that the compressor operates safely and efficiently, it is important to understand the components of the air compressor, including the continuous run unloader valve. This article will provide an overview of this important part of the air compressor system, covering its purpose, installation, and maintenance.

What is a Continuous Run Unloader Valve?

Contents

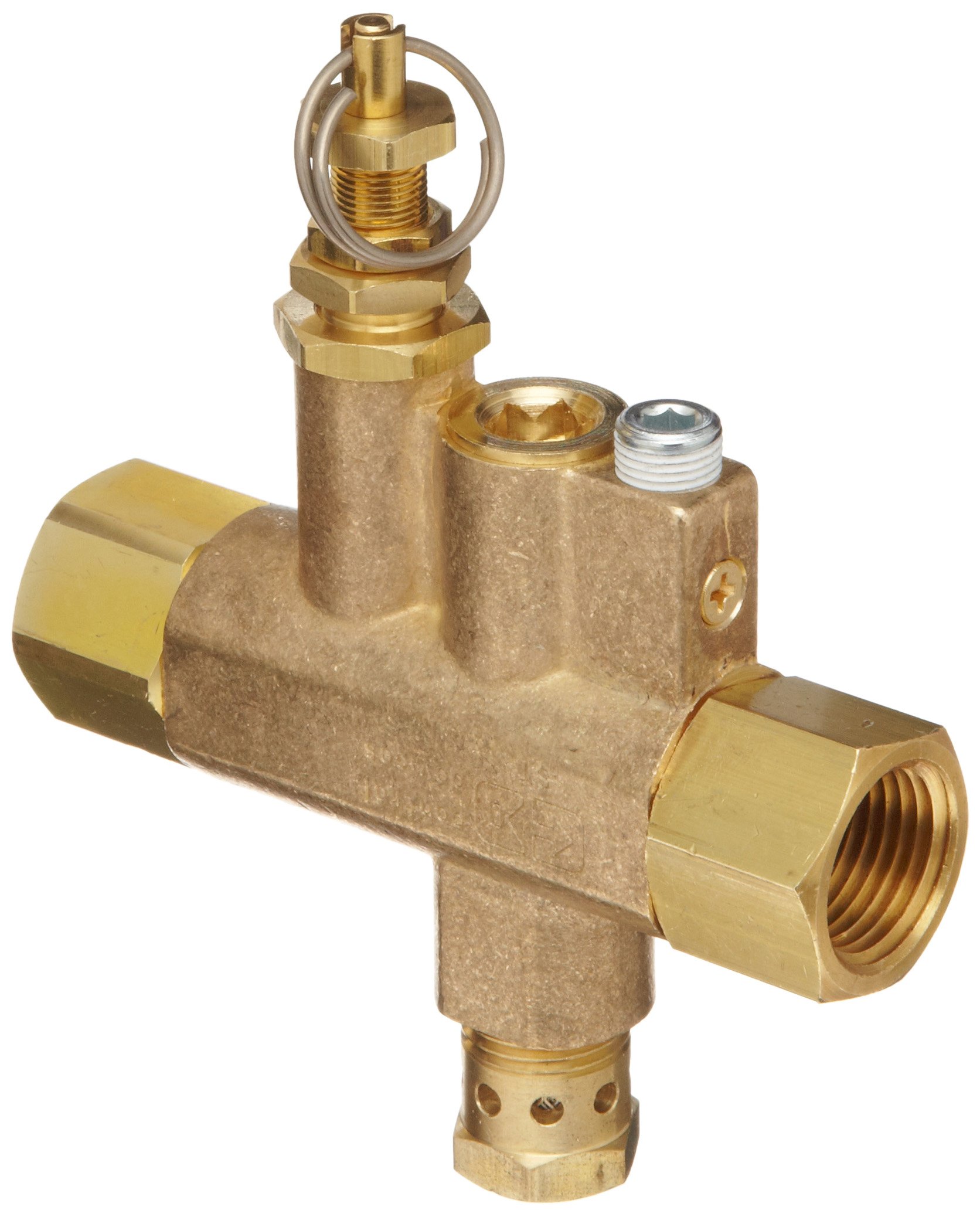

A continuous run unloader valve is a device used to control the amount of pressure in an air compressor. It is placed between the compressor and the air receiver tank, and it is designed to open when the pressure exceeds a certain level. This allows air to escape from the compressor, preventing it from becoming over-pressurized and potentially exploding. The valve is designed to be opened and closed automatically, depending on the pressure in the system.

Installation of a Continuous Run Unloader Valve

When installing a continuous run unloader valve, it is important to first ensure that the compressor is off and all pressure is released from the system. The valve should then be connected to the compressor using the appropriate fittings. The valve should be placed between the compressor and the air receiver tank, and the air line should be connected to the valve’s exhaust port. Once the valve is connected and in place, the system should be checked for leaks and any pressure adjustments should be made.

Maintenance of a Continuous Run Unloader Valve

It is important to regularly inspect and maintain a continuous run unloader valve to ensure that it is functioning properly. The valve should be checked for signs of wear and tear, and any debris or dirt should be removed. The valve should also be lubricated if necessary. Additionally, the valve should be checked periodically to ensure that it is opening and closing correctly and that the pressure is being regulated properly.

In conclusion, a continuous run unloader valve is an important part of an air compressor system, as it helps to regulate the pressure and prevent over-pressurization. Proper installation and maintenance are key to ensuring that the valve is functioning as it should, and it is important to check the valve regularly for signs of wear and tear. With the right care and maintenance, a continuous run unloader valve can help keep an air compressor running safely and efficiently.